Single Stud Turning Robots

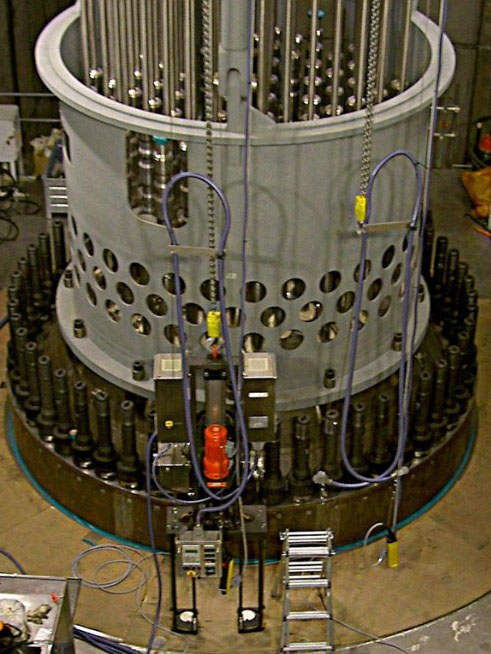

The Single Stud Turning Robot operates on the platform of the Multi Stud Tensioner. It is attached to the rail of the working platform and it is secured in a way to prevent from falling. The robot is automatically operated and controlled at the control console by an operator. Typically, two automatic stud turning robots are provided for a stud tensioning machine in order to ensure redundancy for turning the RV studs.

For operating the two Single Stud Robots only one operator is necessary at the control console. There is no need for operating staff in the cavity. The robot is designed for minimizing the operating staff in the cavity and resulting furthermore to reduction of the radiation exposure.

The robot drives independently from the one RV stud position to the next RV stud position. The RV stud weight compensation during the RV stud turning is controlled and realized by electrical servo control. The RV stud is installed or removed automatically by the robot and safely stored in the MST. The torque and speed for the RV stud turning is monitored, controlled and recorded at the control console. The typical operating time for a Single Stud Turning Robot for removing one RV stud is six minutes.

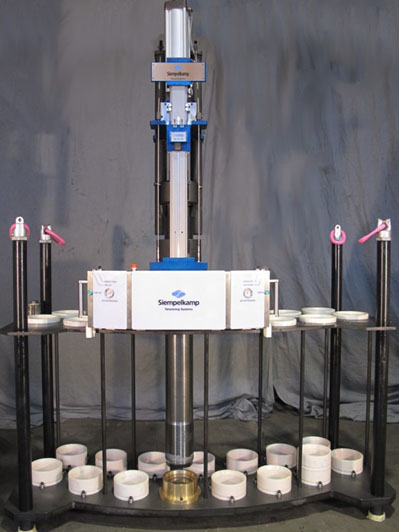

Single Stud Turning Device on a moveable transport frame.

Weight compensated RV Stud turning with pneumatic control via a pneumatic cylinder.

Torque and Speed control during stud installation or removal process.

Parameters for Turning Torque and Speed are adjustable.

Depth position monitoring for semi-automatic procedure.

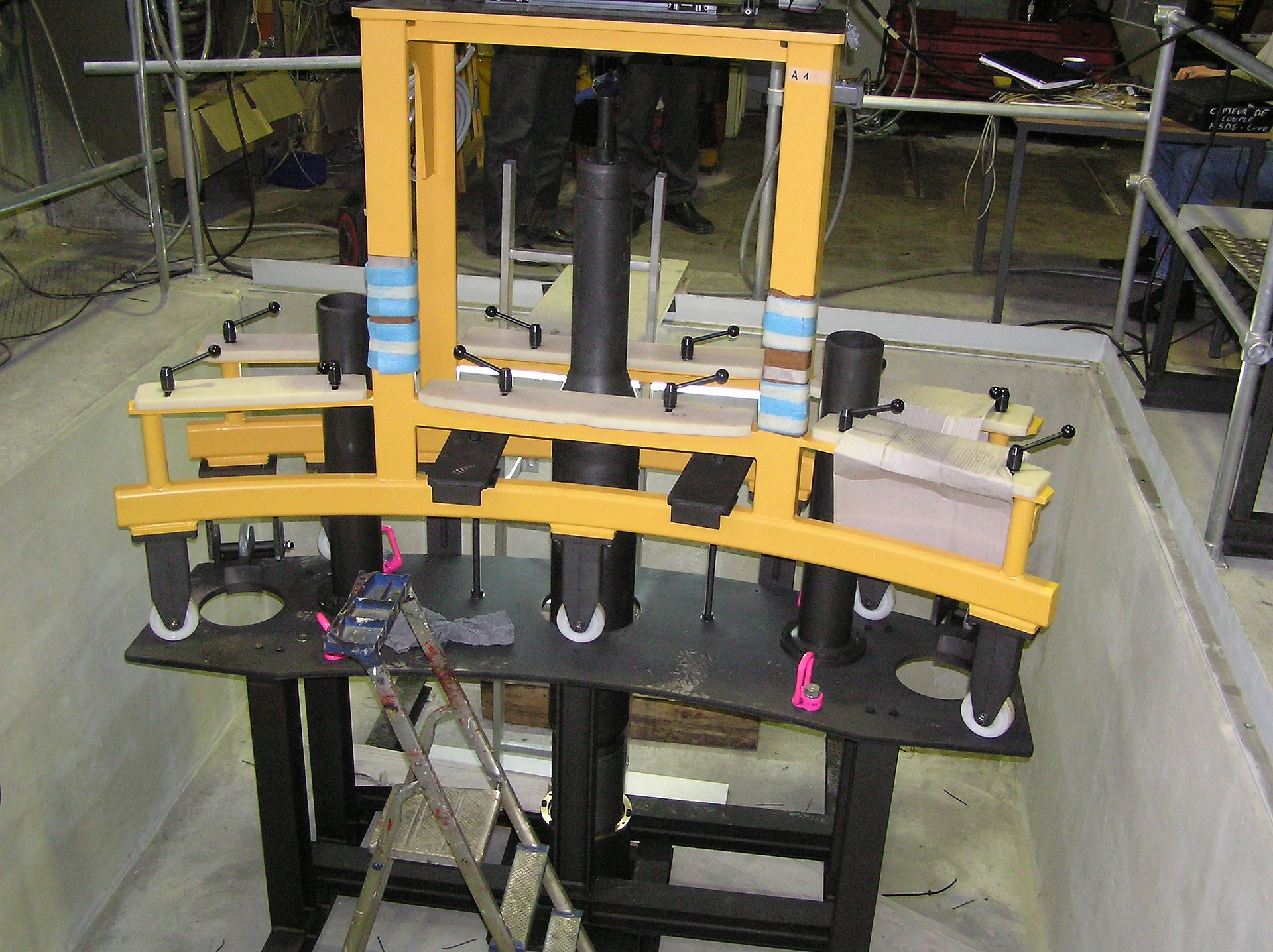

Automated Single Stud Turning Device